1st of a kind pharmaceutical liquid filling and assembly technology is developed for speeds up to 100 cartridges per minute using peristaltic pumps.

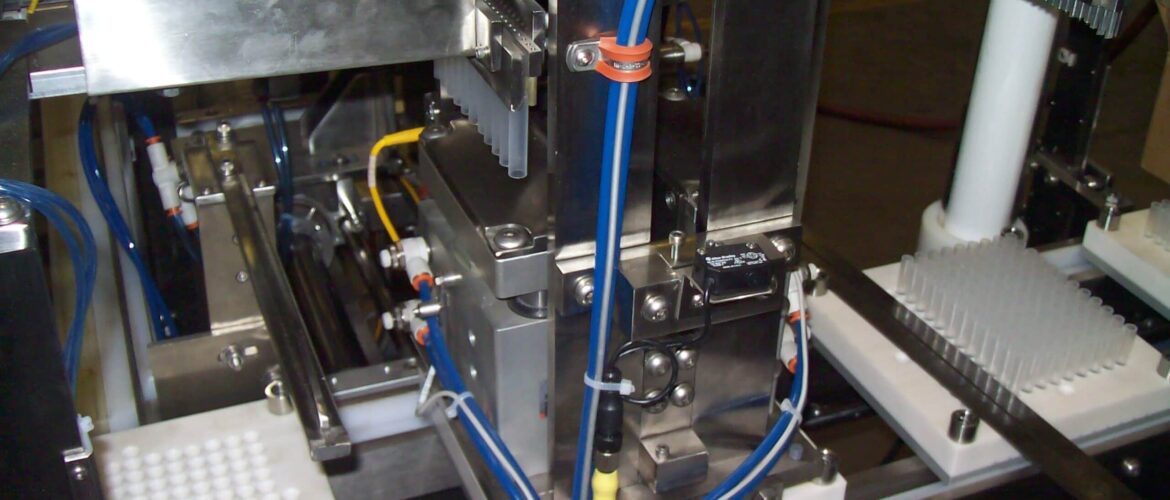

This state of the art machine assembles and fills two style cartridges with a change over taking about 15 minutes. A four component assembly gets filled to the accuracy of +/- .02 ml. The assembled cartridges include: tube, plunger, and needle assembly with stopper and disc. Components are assembled at 12 per cycle with high accuracy of assembly and filling. As parts are assembled vision inspection stations check parts that have been assembled for quality and rejects parts automatically into a tray with registered positions noting the specific rejects. Vision display screens give the operator a view of the inspections. The system is completely washable including the aseptic peristaltic pumps that do not require the parts to be autoclaved. These systems can be set up with disposable filling trains to reduce cleaning, set up time, autoclaving costs and contamination risk.